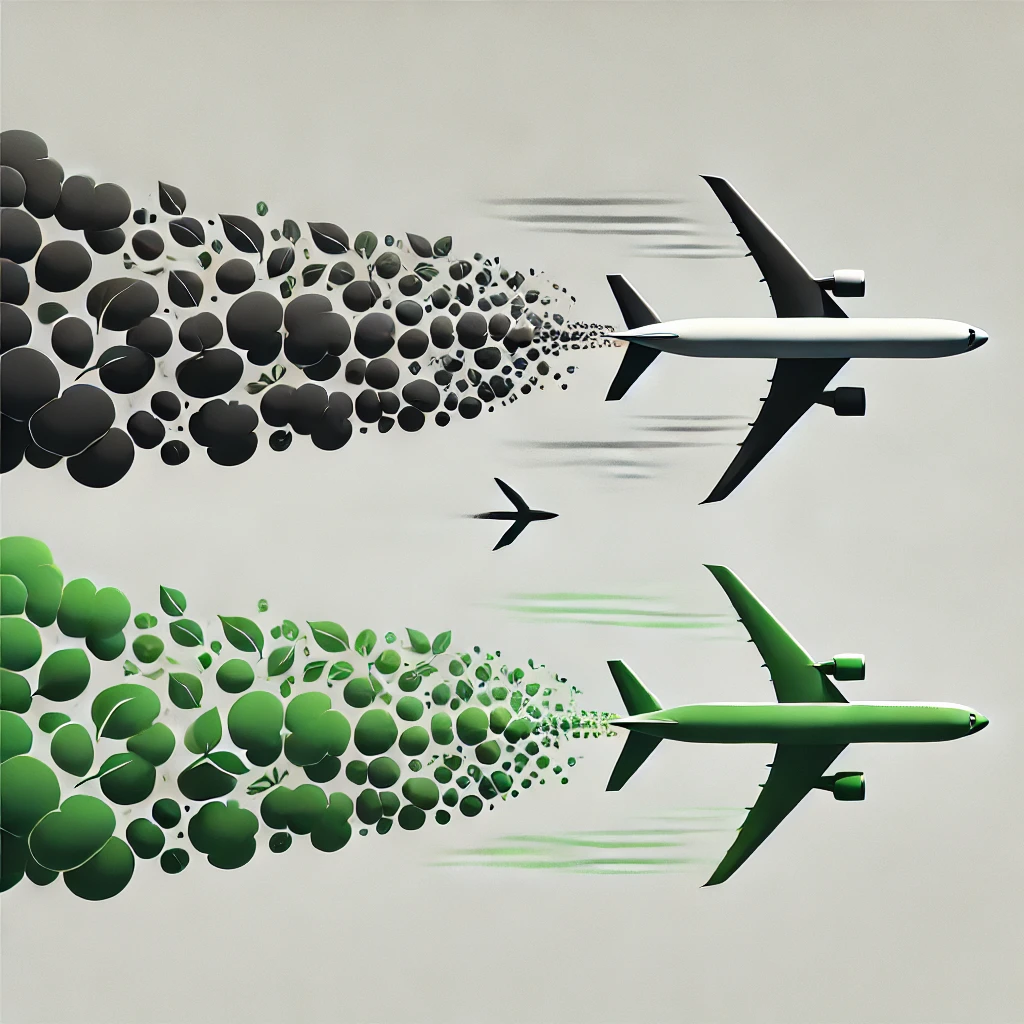

As the aviation industry strives to reduce its carbon footprint, the demand for Sustainable Aviation Fuels (SAFs) has surged. Renewable kerosene, a key component in SAFs, is gaining attention for its potential to replace fossil fuels in aviation. Green methanol serves as an intermediary in producing synthetic kerosene. By using directly the waste heat of green methanol production for SAF production, companies boost efficiency, cut reliance on external energy users, and enhance sustainability.

Aviation is one of the most challenging sectors to decarbonize due to its reliance on high-energy-density fuels. Sustainable Aviation Fuels (SAFs) have emerged as a promising solution, offering significant reductions in lifecycle greenhouse gas emissions compared to traditional jet fuel. Renewable kerosene, a form of SAF, is produced through innovative processes incorporating renewable energy and carbon capture technologies.

The global SAF market is projected to grow exponentially in the coming years. Governments, international organizations, and private companies invest heavily in SAF production to meet ambitious climate targets. For example, the European Union’s “Fit for 55” package mandates increasing the share of SAFs in aviation to 63 percent by 2050. This regulatory support drives innovation and creates new opportunities for sustainable fuel technologies.

According to IATA’s strategy towards net zero CO2 emissions, achieving net zero CO2 emissions by 2050 will require a combination of maximum elimination of emissions at the source, offsetting, and carbon capture technologies. In IATA’s vision, 65 percent of the goal is achieved with Sustainable Aviation Fuel (SAF), 13 percent with new technology, such as electric and hydrogen, and 3 percent with infrastructure and operational efficiencies. The remaining 19 percent will come from offsets and carbon capture.

Green Methanol: A Crucial Component in SAF Production

Green methanol plays a vital role in the production of renewable kerosene. Produced by combining hydrogen generated from renewable electricity with captured carbon dioxide, e-methanol serves as an intermediary in the synthesis of e-kerosene. This Power-to-X (P2X) process transforms renewable energy into fuels or chemicals, offering a pathway to decarbonize aviation and other hard-to-abate sectors.

The advantages of green methanol extend beyond its role as a precursor for green kerosene. It is a versatile chemical feedstock that can also be used in marine fuels, chemicals, and other industries. Its production relies on renewable energy and carbon capture, ensuring a minimal environmental footprint.

Synergies in Integrated Production Facilities

One of the most promising developments in green methanol production is the integration of facilities to optimize energy efficiency. Green methanol production generates significant amounts of waste heat, which can be harnessed to improve the efficiency of adjacent renewable kerosene production plants. This integrated approach minimizes energy losses and reduces overall emissions.

Unlike traditional setups that need e-methanol plants near cities for district heating, this model allows plants to be located more flexibly. By using waste heat directly for SAF production, companies boost efficiency, cut reliance on external energy users, and enhance the sustainability of both e-methanol and SAF. This innovation makes e-methanol production practical in remote or industrial areas, opening new growth opportunities.

Finnish Leadership in E-Methanol Projects

Finland is at the forefront of advancing green methanol technology. Several ambitious projects are underway to establish the country as a leader in sustainable fuel production.

In addition to SSE’s numerous green methanol plant projects, one notable example is the planned green methanol plant in Ranua. It aims to produce 100,000 tons of green methanol annually by 2029. This facility will utilize wind power and captured carbon dioxide to create a sustainable fuel solution for the maritime sector. By leveraging local renewable energy resources, the project demonstrates the potential of green methanol to drive decarbonization across multiple industries.

Another groundbreaking initiative is the green methanol production plant planned for Haapavesi. This facility will use wind energy to produce hydrogen via water electrolysis, which will then be combined with carbon dioxide captured from industrial emissions to synthesize green methanol.

Overcoming Challenges and Unlocking Potential

While the prospects for green methanol and SAFs are promising, significant challenges remain. High production costs, limited availability of renewable energy, and the need for robust carbon capture infrastructure are among the hurdles that must be addressed. Additionally, scaling up production to meet the growing demand for SAFs requires substantial investments in technology and infrastructure.

To overcome these challenges, collaboration between governments, industries, and research institutions is essential. Policies that incentivize investment in renewable energy and carbon capture technologies will play a critical role in accelerating the transition to sustainable aviation fuels. Furthermore, international cooperation is needed to establish harmonized standards and ensure the widespread adoption of SAFs.

Read More:

- European Commission: European Union’s Fit for 55

- IATA: Developing Sustainable Aviation Fuel (SAF)

- US Department of Energy: Sustainable Aviation Fuel

- Science Direct: Sustainable aviation fuel (SAF) production through power-to-liquid (PtL): A combined techno-economic and life cycle assessment

- European Energy: Power-to-X substitutes fossil-fuels and decarbonises industries

- YLE: Ranualle suunnitellaan 800 miljoonan euron vihreän metanolin tehdasta (in Finnish)

- YLE: Haapavedelle suunnitellaan jopa kahden miljardin euron investointeja vihreään energiaan (in Finnish)